Estimating & Tendering

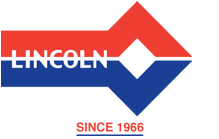

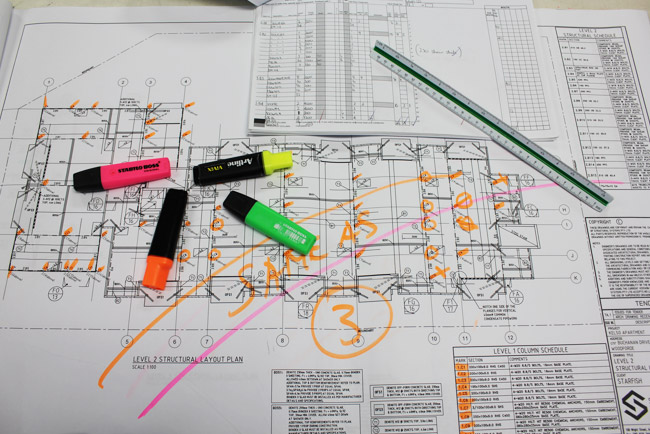

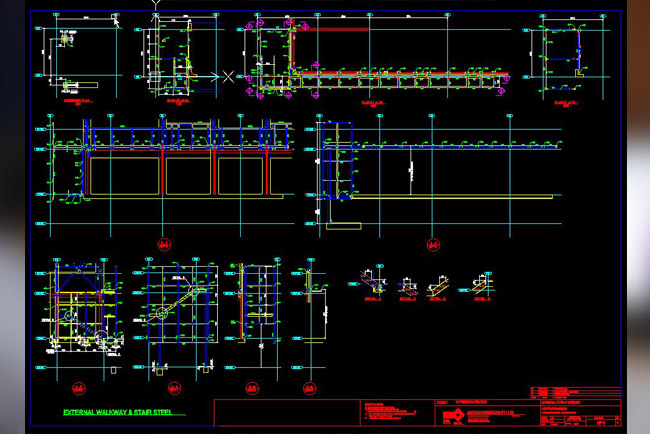

Our in-house estimating teamwork with the local tender and estimating market for new projects. Builders & Developers will send us Architectural & Structural Engineers plans for quoting.

Our estimators are able to accurately measure the cost of steelwork for each individual project using years of experience & industry knowledge.

Our estimating process includes vigorous research to determine the following:

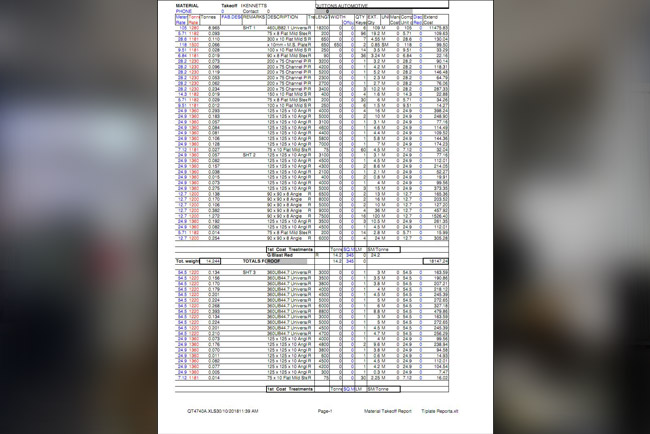

- Take off what steel is required down to every last nut & bolt.

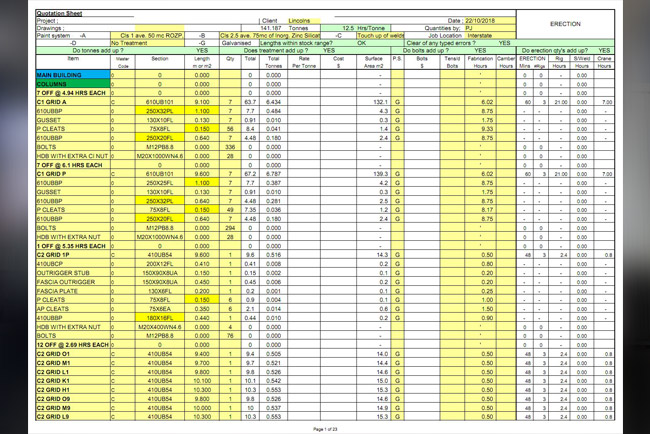

- Determine the necessary labour hours both Workshop & Site Erection based.

- Establish what steel treatment will be required for corrosion protection or decorative finishes to ensure the steel will stand the test of time.

- What Cranes, Boom Lifts & installation machinery is required.

- Any other specialist requirements which may be job specific.

- Look for cost saving initiatives to save the client & provide a competitive advantage over the opposition.

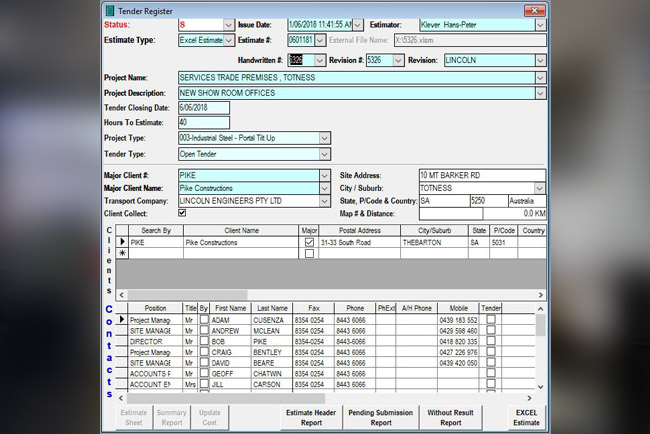

Once the above process is complete we will determine a specific package & tender sum and begin contract negotiations with our prospective clients. If you have a project that you would like us to prepare a quotation for please contact us today..!

3D Design & Drafting

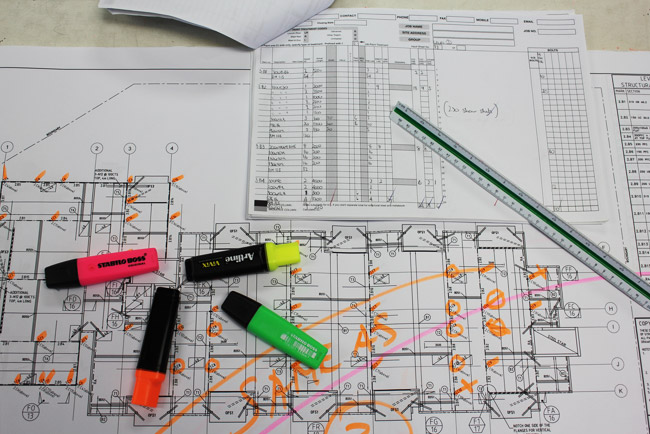

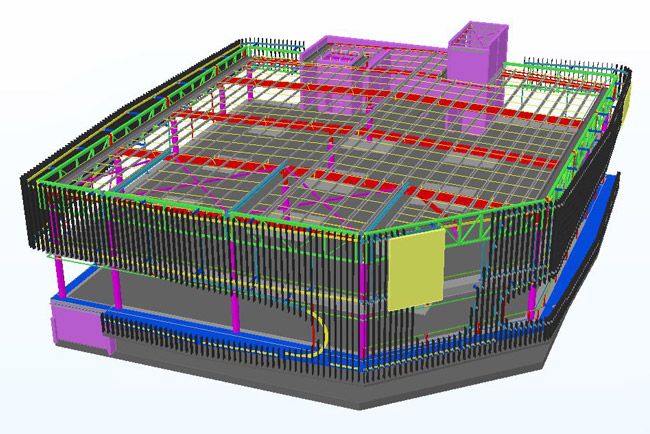

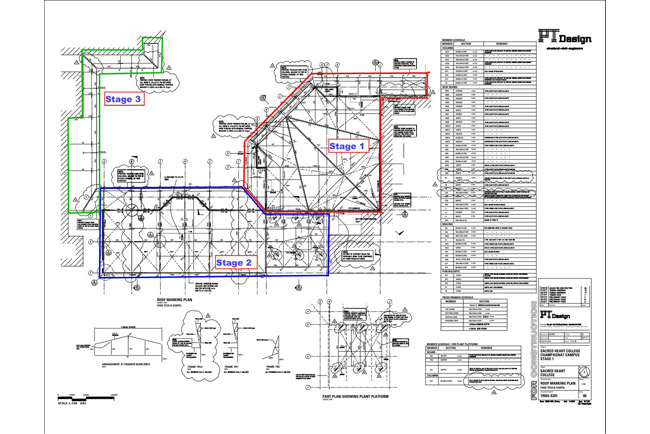

Once we have been awarded a project we begin our extensive 3D design & shop drafting process to determine how we will best achieve the optimal steel structure.

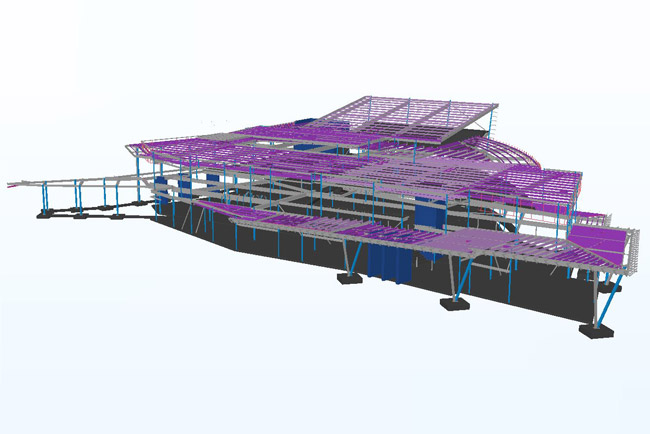

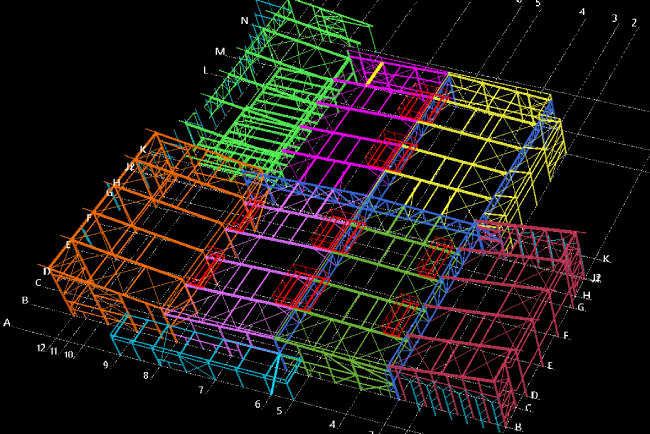

Our draftsman work closely with the Building Designers, Architects & Engineers to understand the project & accurately detail the superstructure. In most cases the structural steel is the backbone of any building with many other building materials integrating with the structural steel to create the modern buildings we see today, precast walls, concrete slabs, windows & roof’s all rely on structural steel. Our design & project team also work closely with the builder to break down the project to coordinate how best to build the structure & tailor the steel solution to meet the needs of the client & project.

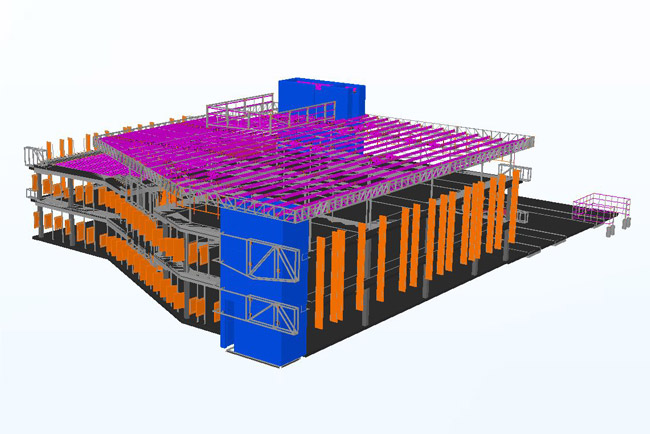

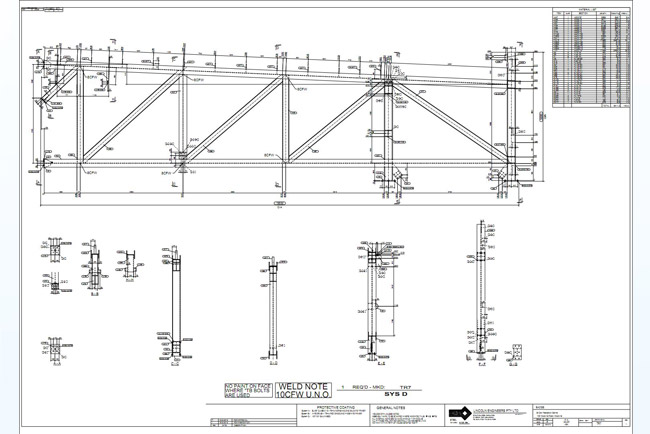

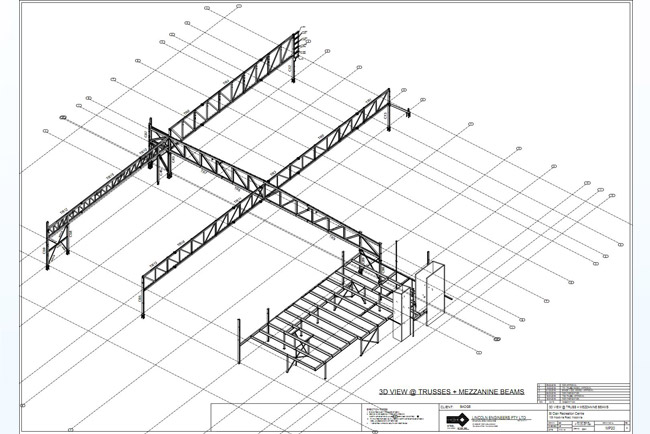

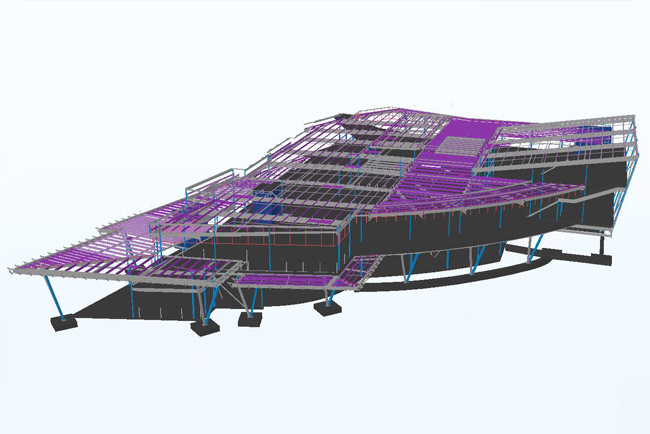

In order to build this 3D BIM Model we use an in-house drafting department utilising the power of Tekla Structures. Tekla Structures is a 3D steel & building materials drafting program capable of detailing structural steel quickly and accurately with the ability to view the structure in a 3D model & coordinate with many other building disciplines as seen in the 3D model pictured here.

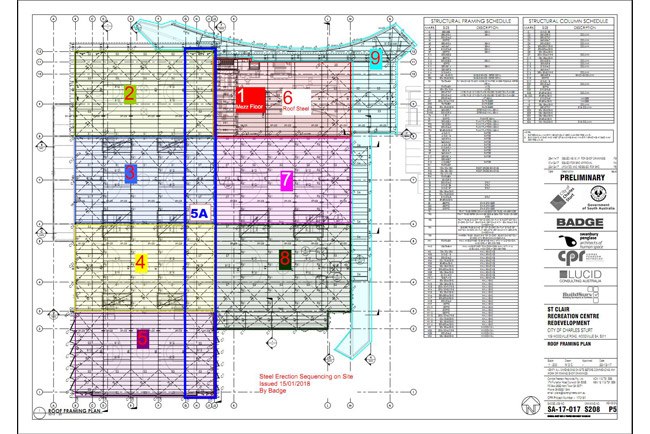

Once the modelling is complete we then create detailed 2D drawings from the 3D model. These drawings reviewed in the office by our production team, materials are scheduled & the workshop pack is then passed onto our manufacturing team on the w/shop floor. These structures can range in size from as little as a couple of pieces to many thousands of pieces of steel.

Planning & Fabrication

At Lincoln Engineers all of our projects are managed in-house by our production & project management team. Our attentive personnel have many years’ experience in the structural steel industry & are capable of handling projects of all shapes & sizes from the simplest structure to the most complex.

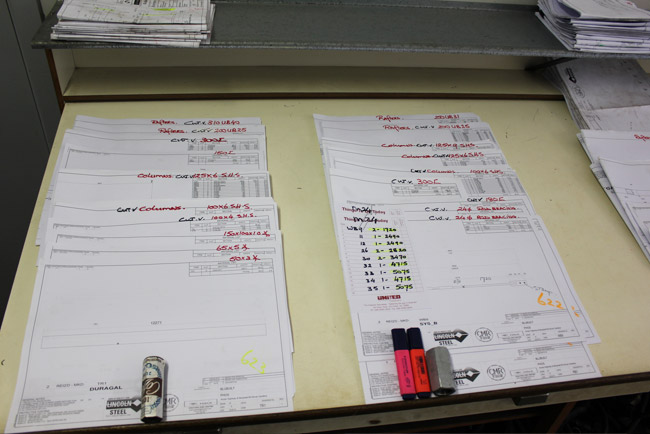

During the planning and fabrication stage of the project we work in consultation with the builder to meet the project demands & requirements looking closely at the design specifications, plans & clients needs. During this phase we schedule the different types and sizes of steel we will require to fabricate the project prior to the drawings being sent of for formal approval by the design consultants.

All of the data for the structure is entered into our Production planning & material resource planning software Ace Soft ERP. This specialised software has been developed in house by Lincoln Engineers & is specialised to our Steel Fabrication industry.

It really is the ultimate tool for the project management of steel structures & allows our project team total control of the project at every stage. Once the data has been scheduled in our office it can be sent to the workshop floor where the steel can then be cut, fabricated and welded to the relevant Australian standards AS4100, AS5131 & AS1554 in order to make all the different components of the building.

At Lincoln Engineering we use our own paint bay for ROZP (Red Oxide Zinc Phosphate) Steel Treatment, all Galvanising, Inorganic Zinc & other specialised top coat paint systems are carried out externally at specialised industrial painters who ensure that the relevant standards are met & that the steel will stand up to the harsh Australian environment for many years to come. Lincoln Engineers works closely with paint manufacturers, Dulux, Akzo Nobel – International Paints, Jotun & PPG just to name a few. In some cases our steel protective coatings can be warranted for a period of 10-15years of life expectancy to the 1st maintenance period providing peace of mind for our clients.

Rigging & Steel Erection

In regards the rigging and steel erection we have the following erection equipment:

- 30 Tonne Mobile Crane Tadano

- 4x Crane Trucks with a capacity up to 6 Tonne

- A fleet of Trucks

- 3x Prime Movers

- Various Semi trailers, Extendable Trailers & Drop Deck Trailers

- Flat Bed Trucks & Tilt Trucks

- 2x 19ft & 1x 32ft Electric Scissor Lifts

- 3x Boom Lifts ranging from 45ft to 60ft

Our equipment is engaged to carry steelwork to and from our supplier’s yards. The elimination of the use of transport companies saves time, increasing overall productivity and efficiency for our clients.

Lincoln Engineers currently employs 15 Erectors, Site Boilermakers, Truck/Crane Drivers and Riggers who work amongst three separate Erection crews. Each crew is accommodated with its own Site Vehicle, Mobile Welders, Scissor Lifts, Boom Lifts and other specialised tools which are necessary for Structural Steel Erection.

In additional to this Lincoln Engineers, also works closely with various Sub Contractors in the Steel Erection Industry which provide a quality service and who work in conjunction with our project management team to ensure a professional job is achieved every time.

- Estimating & Tendering

-

Estimating & Tendering

Our in-house estimating teamwork with the local tender and estimating market for new projects. Builders & Developers will send us Architectural & Structural Engineers plans for quoting.

Our estimators are able to accurately measure the cost of steelwork for each individual project using years of experience & industry knowledge.

Our estimating process includes vigorous research to determine the following:

- Take off what steel is required down to every last nut & bolt.

- Determine the necessary labour hours both Workshop & Site Erection based.

- Establish what steel treatment will be required for corrosion protection or decorative finishes to ensure the steel will stand the test of time.

- What Cranes, Boom Lifts & installation machinery is required.

- Any other specialist requirements which may be job specific.

- Look for cost saving initiatives to save the client & provide a competitive advantage over the opposition.

Once the above process is complete we will determine a specific package & tender sum and begin contract negotiations with our prospective clients. If you have a project that you would like us to prepare a quotation for please contact us today..!

- 3D Design & Drafting

-

3D Design & Drafting

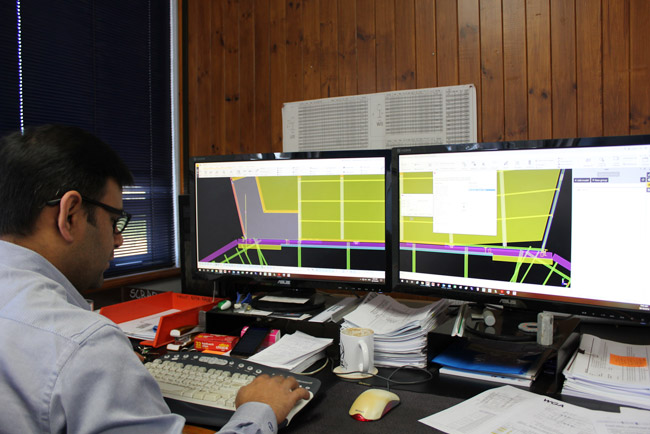

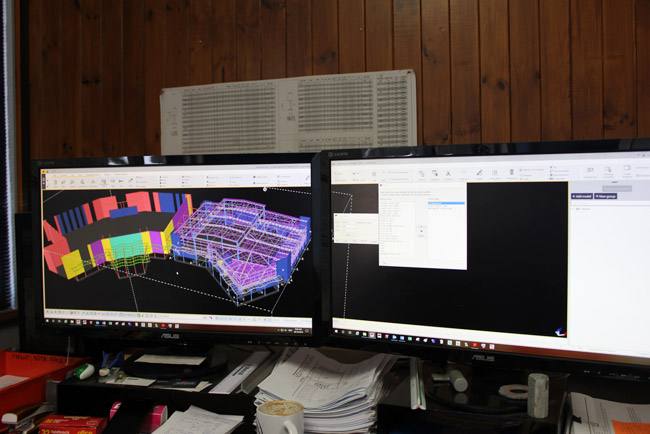

Once we have been awarded a project we begin our extensive 3D design & shop drafting process to determine how we will best achieve the optimal steel structure.

Our draftsman work closely with the Building Designers, Architects & Engineers to understand the project & accurately detail the superstructure. In most cases the structural steel is the backbone of any building with many other building materials integrating with the structural steel to create the modern buildings we see today, precast walls, concrete slabs, windows & roof’s all rely on structural steel. Our design & project team also work closely with the builder to break down the project to coordinate how best to build the structure & tailor the steel solution to meet the needs of the client & project.

In order to build this 3D BIM Model we use an in-house drafting department utilising the power of Tekla Structures. Tekla Structures is a 3D steel & building materials drafting program capable of detailing structural steel quickly and accurately with the ability to view the structure in a 3D model & coordinate with many other building disciplines as seen in the 3D model pictured here.

Once the modelling is complete we then create detailed 2D drawings from the 3D model. These drawings reviewed in the office by our production team, materials are scheduled & the workshop pack is then passed onto our manufacturing team on the w/shop floor. These structures can range in size from as little as a couple of pieces to many thousands of pieces of steel.

- Planning & Fabrication

-

Planning & Fabrication

At Lincoln Engineers all of our projects are managed in-house by our production & project management team. Our attentive personnel have many years’ experience in the structural steel industry & are capable of handling projects of all shapes & sizes from the simplest structure to the most complex.

During the planning and fabrication stage of the project we work in consultation with the builder to meet the project demands & requirements looking closely at the design specifications, plans & clients needs. During this phase we schedule the different types and sizes of steel we will require to fabricate the project prior to the drawings being sent of for formal approval by the design consultants.

All of the data for the structure is entered into our Production planning & material resource planning software Ace Soft ERP. This specialised software has been developed in house by Lincoln Engineers & is specialised to our Steel Fabrication industry.

It really is the ultimate tool for the project management of steel structures & allows our project team total control of the project at every stage. Once the data has been scheduled in our office it can be sent to the workshop floor where the steel can then be cut, fabricated and welded to the relevant Australian standards AS4100, AS5131 & AS1554 in order to make all the different components of the building.

At Lincoln Engineering we use our own paint bay for ROZP (Red Oxide Zinc Phosphate) Steel Treatment, all Galvanising, Inorganic Zinc & other specialised top coat paint systems are carried out externally at specialised industrial painters who ensure that the relevant standards are met & that the steel will stand up to the harsh Australian environment for many years to come. Lincoln Engineers works closely with paint manufacturers, Dulux, Akzo Nobel – International Paints, Jotun & PPG just to name a few. In some cases our steel protective coatings can be warranted for a period of 10-15years of life expectancy to the 1st maintenance period providing peace of mind for our clients.

- Rigging & Steel Erection

-

Rigging & Steel Erection

In regards the rigging and steel erection we have the following erection equipment:

- 30 Tonne Mobile Crane Tadano

- 4x Crane Trucks with a capacity up to 6 Tonne

- A fleet of Trucks

- 3x Prime Movers

- Various Semi trailers, Extendable Trailers & Drop Deck Trailers

- Flat Bed Trucks & Tilt Trucks

- 2x 19ft & 1x 32ft Electric Scissor Lifts

- 3x Boom Lifts ranging from 45ft to 60ft

Our equipment is engaged to carry steelwork to and from our supplier’s yards. The elimination of the use of transport companies saves time, increasing overall productivity and efficiency for our clients.

Lincoln Engineers currently employs 15 Erectors, Site Boilermakers, Truck/Crane Drivers and Riggers who work amongst three separate Erection crews. Each crew is accommodated with its own Site Vehicle, Mobile Welders, Scissor Lifts, Boom Lifts and other specialised tools which are necessary for Structural Steel Erection.

In additional to this Lincoln Engineers, also works closely with various Sub Contractors in the Steel Erection Industry which provide a quality service and who work in conjunction with our project management team to ensure a professional job is achieved every time.